Pilot Case 3: Catalonia (ES)

Catalan pilot site in Sant Quirze del Vallès

Agència de l’Habitatge de Catalunya (AHC) selected a 2003’s residential property located in Sant Quirze del Vallès (25 km from Barcelona, Catalonia) for the Catalan pilot site. It is owned by INCASÒL but managed by AHC. It is a U-shaped public social housing consisting of 3 independent rectangular blocks.

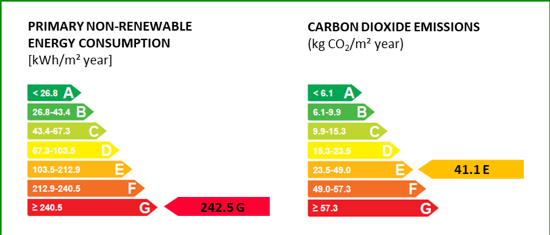

The building was built previously to the current Spanish technical code (CTE), which sets the minimum requirements to comply in the construction sector. This means that its energy demand is very high, rated G in the energy performance certificate (Figure 2). However, there is a solar thermal installation in the rooftop of block A (18.6 m2), which covers up to the 60% of the domestic hot water demand.

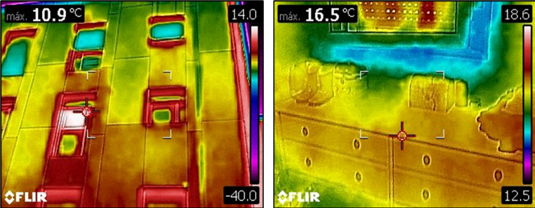

All apartments are heated by electric radiators and have natural ventilation. Some of them show condensation troubles. Both humidity problems and poor thermal comfort (Figures 3 and 4) are related to some damage detected in the external cladding of the façades of all 3 blocks.

With the aim of improving the dwellings’ habitability and increasing their energy efficiency, AHC decided to carry out a complete remodelling process, of which PnH is a part.

All PLUG-N-HARVEST actions are focused on Block A (Figure 1), which has a ground floor with 1 commercial premises and 3 floors with 2 apartments each one. Walls and roofs are insulated while windows are double-paned.

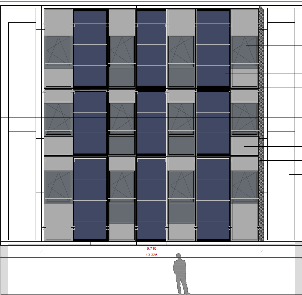

The main façade faces south while the service façade, where the access to the apartments is located, faces north. The ADBE system will be implemented on the main façade, covering an area of 101 m2. It will cover the exterior surface of 6 homes.

This demo site is placed in a Mediterranean climate zone, with warm and dry summers and mild, wet winters.

Site preparation and ADBE system design

Block A, was suitable for the project and structurally sound. This included asbestos and electrical studies as well as an energy diagnosis. Scale drawings of the property were also prepared.

The project contracted a Spanish cladding company, Garcia Faura (GF), to design the ADBE modules to be installed on the south facing of Block A. The 21 ADBE modules to be implemented in this pilot case consists of assembled aluminium panels that include an internal thermal insulation layer to reduce heat loss and exterior photovoltaic panels of amorphous silicon to generate electricity (in our case, with a photovoltaic installed capacity of 6.22 kWp) (Figure 5). Thermal insulation and photovoltaic panels will only be installed on the opaque elements. The energy generated will be equally distributed to all homes in the property. The system will have plug-n-play features reducing the length of installation work.

Current situation

The objectives, structure, and solution of the PLUG-N-HARVEST project were explained in detail to the tenants of Block A and other key actors with the aim of involving them within the project and increasing their commitment to the innovative ADBE modules to be implemented. A proper use of the innovative technology by the end-users is crucial to achieve success.

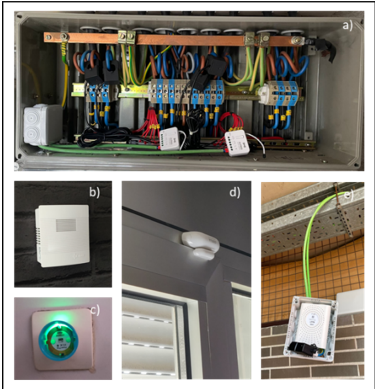

To understand the relationship of the building performance as well as to evaluate the results of the ADBE modules installation, it is necessary to collect, process, and analyse some data related to energy demand, energy generation, energy consumption, occupant’s behaviour, indoor environmental conditions, thermal comfort, and satisfaction. Consequently, the parameters to be collected were defined and consequently a monitoring system was designed. 2 indoor air quality sensors, 2 open window sensors, 8 smart plugs and 1 electric meter were installed in each of the 6 apartments in the Block A (Figure 6). These smart sensors have been collecting and sending data via a raspberry pi to project partners since May 2021 (prior data to the implementation of the ADBE modules). A meteorological station and a pyranometer were also installed in the rooftop of the Block A to get data of the weather conditions.

Meanwhile, the ADBE façade profile was designed through an innovative contract, and the mould for its manufacturing was created. The profile was fabricated using this mould and then it was shipped to GF factory, where the prototype and the ADBE façade panels will be assembled.

n mid-March 2022, a visit to GF facilities took place and the act of works beginning was signed.

Next steps

The laboratory-scale testing of the façade system prototype is due to be done in late March 2022, and then the full-scale module fabrication will begin. The site preparation and installation of the external wall insulation started in mid-March 2022. The construction works (including the ADBE modules installation) are scheduled to be finished in end of May 2022 and post monitoring will continue until 31st August 2022. Pre and post monitoring data will be treated and analysed for a final evaluation of the results in terms of energy and comfort impacts.