Pilot Case 4: Grevena (GR)

Greek Pilot site in Grevena

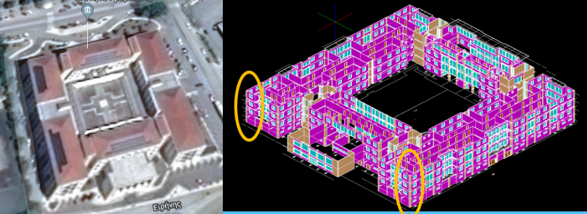

Region of Western Macedonia offers as a pilot demonstrator of the ADBE system, the Public building of Region located in Grevena city. The building of 13.778,40 m2, which currently hosts municipal and regional authorities and employees of the City of Grevena, was constructed in 1997, with 180 offices and 3 floors. Walls, roof and floors are insulated while the windows are double glassing. The average annual temperature is 12.4 °C in Grevena while the rainfall averages at around 723 mm per year. The city of Grevena presents high temperature differences between summer and winter and between morning and noon and is considered one of the coldest areas in Greece. The building belongs to climate zone D, according to building energy regulation (KENAK). Walls, roofs, and floors are insulated while the windows are double glassing.

The pilot façade will be implemented in the southeastern and southwestern surfaces of the building as indicated below (Figure 1) and will cover the second and the third floor, in order to achieve the maximum electrical and thermal energy gains, on an annual basis. In total, the facade will cover the exterior surface of 4 offices, one on each floor and wing.

In the building, there is already installed an autonomous PV system of 60 kWp with an on-line monitoring system combined with other energy-saving measures (air-water heat pump, LED lightening, compensation capacitors and solar charging station for e-bikes).

The proposed façade system consists of assembled aluminum panels that include an internal thermal insulation layer to reduce heat loss and exterior photovoltaic panels of amorphous silicon to generate electricity. The system will have a total thickness of 20 cm while there is a gap between the thermal insulation layer and the glass panel for cable routing. Thermal insulation will only be installed on the opaque elements, while in the openings will be mounted only PV panels.

The system will also include suitable inverters, load regulators and other electrical equipment. In addition, a heat recovery mechanical ventilation system will be installed in each office in order to ensure air quality while achieving further energy savings. The façade system will have plug-n-play features reducing the length of installation work.

In brief, the basic elements of PLUG-N-HARVEST system in Grevena (to be installed by RENEL company) are:

- Aluminum frames

- Thermal insulation Layer

- Photovoltaic panel of amorphous silicon

- Mechanical ventilation system with heat recovery

- Inverters

- Charge controllers

- Batteries

- Cables and other electrical equipment

In order to understand the relationship of building performance, energy demand, energy generation, occupant’s behaviour, thermal comfort and satisfaction, it is necessary to collect, process, and analyse a variety of data sources from smart meter reading (e.g. energy consumption, occupancy, indoor environmental conditions, etc.). In this context, data are automatically collected by smart sensors as well as other proprietary equipment installed at the selected pilot site in Grevena. In more detail, two types of data are collected, namely:

- Data necessary to monitor the contextual conditions (energy consumption, temperature, humidity, weather, etc.) of the pilot site and

- Data related to the occupancy evaluation techniques (questionnaires, interviews and workshops with key building users and managers) of the actual use case end-users.

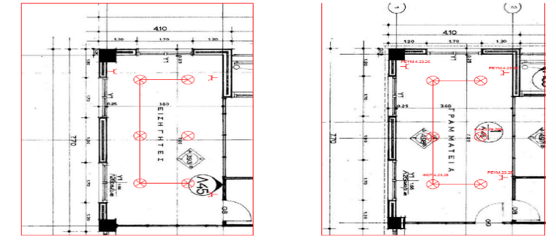

The installation of measuring equipment for the needs of energy pilot facade of Regional Unit of Grevena (Plug-n-Harvest project) has been completed and working since July 2021. The equipment can conduct intelligent automated measurements at four offices of the Region building in Grevena. The equipment installed at four offices is located on the SE (No 393 and No 498) and SW (No 362 and No 458) side of the building behind the pilot façade.

The sensors transmit their measured values to several Raspberry Pie single-board computers

positioned in the offices. Via the WLAN network of the Region Unit the measured values will be stored on an institute server.

The following sensor types have been installed in all four (4) offices:

- Temperature and humidity sensors + USB dongle (4 items)

- Temperature, motion, light sensors + USB dongle (4 items)

- Door-window sensors + USB dongle (12 items)

- Energy meters for sockets/lights with RPI (14 items)

- Smart sockets for energy consumption of connected devices +USB dongle (12 items)

- Calorimeters for energy consumption of thermal radiators + RPI (4 items)

- Thermostatic valves (4 items)

- CO2 sensors + USB dongle (4 items)

- Weather station (1 item)

- Wifi repeaters (4 items)

Next steps

- Conclude the pre monitoring of the pilot site before the installation of ADBE

- Full installation of the ADBE until end of March 2022

- Post-monitoring of the pilot site after the installation of ADBE

- Evaluation of results and finalization of the relevant deliverable until May 2022